Prefabricated Homes – Affordable and Efficient Housing Options with Fast Installation

Prefabricated homes represent a revolutionary approach to modern housing, offering homeowners a faster, more cost-effective alternative to traditional construction methods. These factory-built structures combine innovative manufacturing techniques with quality materials to deliver complete housing solutions in significantly less time than conventional building processes.

The housing market continues to evolve with innovative construction methods that address growing demands for efficient, cost-effective residential solutions. Prefabricated homes have emerged as a compelling alternative to traditional construction, combining modern manufacturing techniques with architectural flexibility to deliver quality housing options that can be completed in months rather than years.

What Are Prefabricated Homes and How Do They Work?

Prefabricated homes are residential structures manufactured in controlled factory environments before being transported and assembled at their final locations. The construction process involves creating standardized components or entire sections in specialized facilities where quality control, weather protection, and efficient workflows optimize production. These homes utilize engineered materials and precise manufacturing techniques to ensure structural integrity while maintaining consistent quality standards across all units.

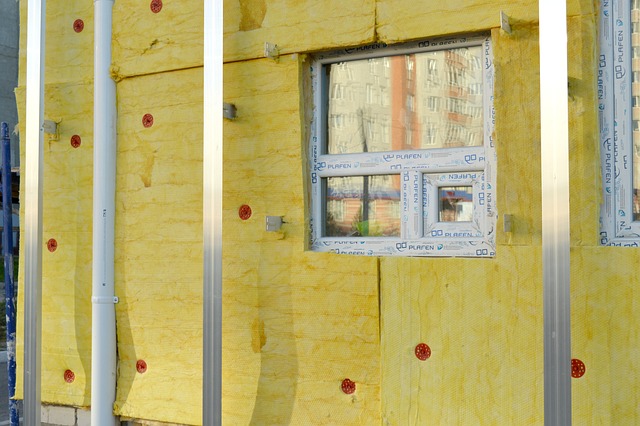

The manufacturing process typically involves creating wall panels, floor systems, and roof assemblies in climate-controlled facilities. Workers use specialized equipment and assembly lines to construct components with precision that often exceeds traditional on-site building methods. Once completed, these sections are transported to the building site where they are assembled on prepared foundations, connected to utilities, and finished according to local building codes.

Why Choose Efficient Prefabricated Homes Over Traditional Construction?

Prefabricated construction offers several advantages over conventional building methods, including reduced construction timelines, improved quality control, and minimized weather-related delays. Factory environments provide consistent working conditions that enable year-round production regardless of seasonal weather patterns. This controlled setting also allows for more precise construction techniques and quality assurance measures that can be difficult to achieve on traditional construction sites.

Environmental benefits include reduced material waste through optimized manufacturing processes and improved energy efficiency through standardized insulation and sealing techniques. The factory setting enables better resource management and recycling of construction materials, contributing to more sustainable building practices. Additionally, the reduced on-site construction time minimizes disruption to surrounding areas and reduces the environmental impact of extended construction activities.

How Fast Can Prefabricated Homes Be Installed?

Installation timelines for prefabricated homes vary depending on the complexity of the design and site preparation requirements, but most projects can be completed within 3-6 months from order to occupancy. The manufacturing phase typically requires 6-12 weeks in the factory, while on-site assembly usually takes 2-4 weeks once the foundation is prepared and utilities are available.

Site preparation remains a critical factor in overall project timelines, as foundation work, utility connections, and local permit approvals must be completed before assembly can begin. However, since manufacturing occurs simultaneously with site preparation, the overall project duration is significantly reduced compared to traditional construction methods that require sequential completion of each phase.

What Design Options Are Available for Modern Prefab Homes?

Contemporary prefabricated homes offer extensive customization options that rival traditional construction flexibility. Manufacturers provide various floor plans, exterior finishes, interior layouts, and architectural styles to accommodate diverse preferences and local aesthetic requirements. Many companies offer modular designs that can be combined or modified to create unique configurations while maintaining manufacturing efficiency.

Interior customization includes flooring materials, cabinetry options, appliance packages, and fixture selections that allow homeowners to personalize their living spaces. Exterior options encompass siding materials, roofing styles, window configurations, and architectural details that can be adapted to complement neighborhood aesthetics or personal preferences. Advanced manufacturers also offer smart home technology integration and energy-efficient systems as standard or optional features.

How Much Do Affordable Prefabricated Homes Actually Cost?

Prefabricated home costs vary significantly based on size, design complexity, location, and included features. Understanding the pricing structure helps potential buyers make informed decisions about this housing option.

| Home Size | Provider Type | Cost Estimation |

|---|---|---|

| 1,200 sq ft Basic | Regional Manufacturer | $80,000 - $120,000 |

| 1,500 sq ft Standard | National Brand | $120,000 - $180,000 |

| 2,000 sq ft Custom | Premium Manufacturer | $180,000 - $280,000 |

| 2,500 sq ft Luxury | Specialty Builder | $280,000 - $400,000 |

These cost estimates typically include the manufactured home structure but may not include site preparation, foundation work, utility connections, or local permit fees. Additional expenses can include land costs, financing fees, insurance, and ongoing maintenance. The total project cost often ranges from 20-40% less than comparable traditional construction when all factors are considered.

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Long-term Value and Considerations

Prefabricated homes can offer excellent long-term value through reduced construction costs, energy efficiency, and modern building techniques. Many manufacturers provide warranties on structural components and systems, offering protection that may exceed traditional construction guarantees. However, factors such as local zoning regulations, financing options, and resale values should be carefully evaluated before making purchase decisions.

The prefabricated housing industry continues to evolve with technological advances and changing consumer preferences. Modern manufacturing techniques, sustainable materials, and innovative designs position prefabricated homes as viable long-term housing solutions that can adapt to future needs while maintaining affordability and efficiency standards that appeal to diverse homeowner demographics.